I’ve been practicing and teaching meat curing for a few decades, it’s my passion to share the slowest food in the world on this website.

This salt-curing method is precise and produces more consistent results. I’ve used it for hundreds of meat curing projects over the years.

It’s got some nuances I want to cover.

Curing meat at home is not labor-intensive; it’s more about using time to preserve it and develop a deeper flavor. It’s part craft and part science.

Cooked meat undergoes a denaturing process, during which the structure changes. Similarly, salt has a denaturing effect and changes the structure of proteins (in slightly different ways).

Raw meat has a high water content, and bacteria thrive in moisture. Salt-dried cured meat removes that moisture.

Dry Curing Meat

Using salt, fermentation, and the drying effect creates complex flavors that epitomize intense umami/savoriness.

(Salt) Dry Curing is a method of intensifying flavor, adding complexity with acidity (introduced or natural) and preserving the incredible flavor.

The water content in the meat is reduced to a point where the meat flavor is amplified and preserved. Unwanted bacteria that spoil meat need moisture and water movement inside the meat (water activity—aw) to thrive.

Dry-curing classics—like Parma Prosciutto, Speck, Bresaola, or Pancetta—are just some of the incredible dry-cured meats you (and I) can make at home.

Technique Equilibrium Curing

A tablespoon of one brand of kosher salt may weigh differently from a tablespoon of another brand of kosher salt – It can create variations when following a recipe.

Using accurate weighing scales that have accuracy to 1-2 decimal places to measure exact quantities is ideal. There is the traditional method also, which I’ll link to and explain.

Accurate scales are probably the most essential equipment if you use the equilibrium curing method because you will deal with minimal amounts of salt, spices, and nitrates.

Here is what is happening with the salt and meat during curing & drying phase:

Osmosis – Salt draws moisture out of the meat, creating an environment that inhibits bacterial growth. This dehydration effect helps preserve the meat.

Diffusion – Salt penetrates the meat over time, equalizing its concentration throughout the tissue. This process ensures the meat is appropriately cured inside and out.

Binding – Salt interacts with proteins (especially myosin), changing the meat’s texture and allowing it to retain some moisture while forming a firmer structure.

Key Ingredients

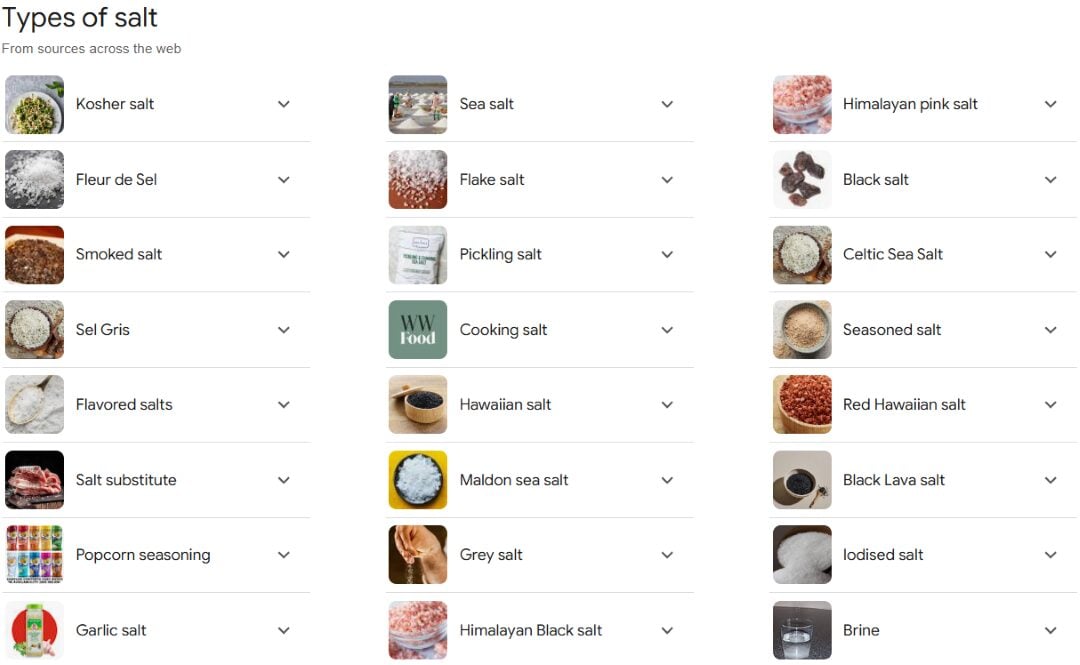

Salt – Size & Type

Salt is the cornerstone of all food curing.

The curing involves salt, and confusion occurs about the curing being the nitrate agent—which is more of an additive agent (protects, speeds up curing, can change colour to pinkish).

There are so many different brands and shapes of salt because different salt shapes & brands have

The key to dry-cured meat is to use sea salt- without additives, anti-caking agents, or iodine.

That means sea salt or kosher salt.

Nitrate/Nitrites

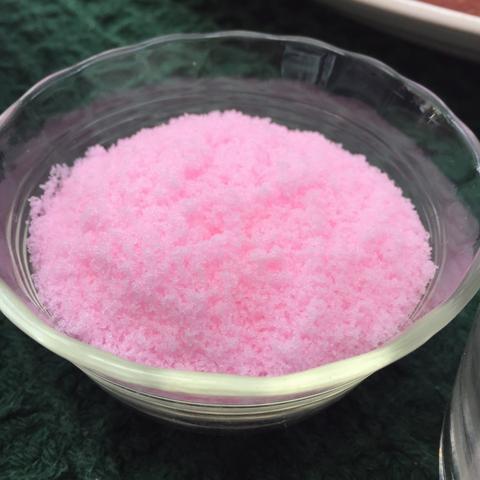

Many home-curing enthusiasts and commercial producers use a curing salt. It’s approximately 90% salt and has sodium nitrite. The curing salts labelled No.1 have only nitrite for under 30-day curing projects.

No. 2 is used for meat curing projects over 30 days.

Known by many names:

- Pink Curing Salt

- Instacure

- Prague Powder

When doing equilibrium curing, curing salt is always added at a ratio of 0.25% to the total weight of the meat.

Example: for 1,000 grams of meat, TOTAL Salt for Cure 2.5%

0.25% of this could be pink curing salt

- TOTAL SALT = 25 grams

- Sea Salt – 22.5 grams

- Pink Curing salt 2.5 grams

For more on pink curing salts, nitrates and nitrites – I wrote an article here.

Choosing the Meat

Fresh, well-cared-for animals yield superior flavor in dry-cured meat, as flavor is intensified.

You can use many primary cuts of pork, such as front leg, back leg, loin, belly, and jowl. Any part of these cuts could also be used. I wrote an article about cuts of meat here for more details.

Unaged, as fresh as possible, or frozen, can be used if thawed carefully and frozen fresh.

Learning how to dry cure meat is much easier when using boneless meat. Using cuts of meat (article on cuts of meat for meat curing I wrote here) that don’t have significant cuts or exposure to oxygen also makes the curing more straightforward and less complex than dry-cured salami (inside the whole meat muscle, it hasn’t been exposed to oxygen, etc).

Fat, however, has much less water, so it does not lose as much weight when dry-curing. Lardo, which is 95% pork fat, is a good example. (Italian Classic – salt-dry-cured slab of pork fat)

Salt curing occurs to penetrate and cure—it does not have a hanging/drying phase (it’s part of the recipe suggestions below).

Dry curing meat follows one of two methods: saturation/salt box or equilibrium curing.

There is a traditional way (saturation/salt box – more on that method here) that’s about when the meat is in the salt cure, covered in salt.

This article will focus on the more precise, accurate, and consistent equilibrium curing method for dry curing meat at home.

Drying cured meat (link to charcuterie/dry cured meats category list on this site)

Equipment and Materials

- Kitchen Scales

- Mortar & Pestle / Spice Grinder

- String, Butcher Twine or Jute

- Mortar & Pestle or Spice Grinder

- Thick String, Butcher Twine

- Meat Drying Area/Chamber

Kitchen Scales

Accurate scales are essential for the correct amount of sea salt, spices, and curing salt.

Ideally, 1 to 2 decimal places. Pocket scales are great for this task, I’ve found.

I’ve a page that suggests precise aspects of scales for this method here.

Mortar & Pestle / Spice Grinder

I use a simple spice grinder (similar to a small coffee grinder) to get a proper, even coating and make the curing process as easy as possible.

The salt and spices become a powder that works well with equilibrium curing.

Or, if you want a manual approach, you have to grind it up with a mortar and pestle.

For a few grinding tools, I wrote a page (near the bottom) about the ones I like here.

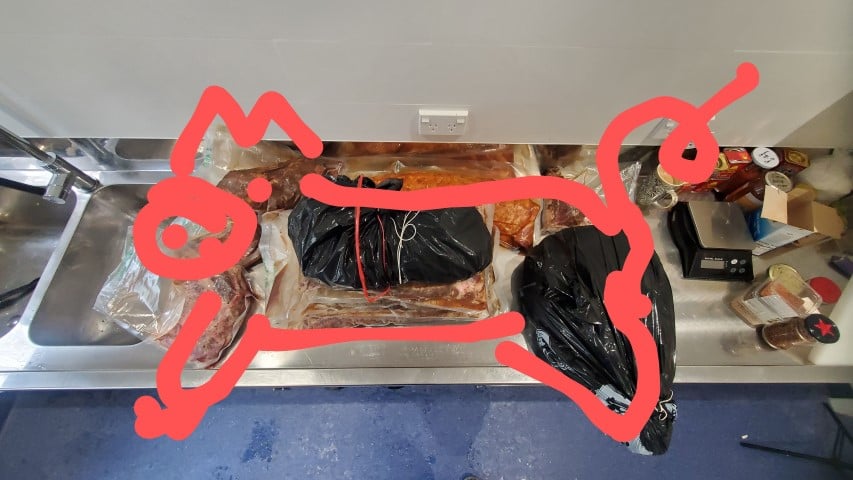

Bag or Container for Curing

Some container holds the salt and meat together to allow osmosis, diffusion, and binding.

The bag is all about equalizing the salt evenly through the meat to the center

Butcher Twine, S hook, or Twine

To create a loop for the hanging cured meat so it isn’t in contact with anything, gravity and airflow assist in the drying/weight loss process.

A S-shaped hook is the alternative; pi k non reactive metal so the meat doesn’t taint.

Casings or Muslin Cloth

I’ve often not used any casings, but it’s advisable when starting, too, since you’ll be able to see what’s happening on the surface of the meat during the drying stage.

What can be used as a ‘barrier’ to prevent/regulate the drying of cured meat?

- skin from the animal (like prosciutto)

- collagen sheets

- muslin cloth

- salt-preserved animal casings/bungs (intestines)

Meat Drying Area / Chamber

Several options can be used—the more conducive the drying environment, the more consistent and successful the outcomes.

Suppose you don’t have this equipment/chamber. In that case, you may be able to find the appropriate environment in or around your home, with some testing using a hydrostat, thermometer, or weather station.

Bought or DIY curing chamber

In this environment, you’ll generally work in 75% humidity and 11°C/50°F. This is usually the accepted whole-muscle Salumi or dry-cured setting temperature, but it can be varied depending on the project.

Here is a full article after I’ve put together many DIY curing chamber conversions.

Cellar, Shed, Wine Cellar

If you have a cold enough winter and around 11-15°C /50-60°F, then you can use this environment to try dry-curing some meat. I recommend you check out the humidity to know roughly what it does.

Don’t expect every project to go perfectly in an open area or cellar; many more factors can be at play if you hang in an exposed area.

The PDF below covers all the options for drying cured meat at home.

For short-term dry curing, like regular fridge curing (done in 4 weeks or less)

How to Make Dry-Cured Meat At Home

Key Points

- Humidity and Temperature: For ideal drying conditions, maintain a slightly humid (65-80%) and cool (50-60°F/10-15°C) environment.

- Equipment and Ingredients: Quality meat, accurate scales, salt and spices are essential for successful outcomes with dry curing.

- Air exchange or airflow – some is needed

Salt Dry Curing

Step 1 – Weigh Meat and Record

You weigh the meat or muscle group first to calculate the amount of each ingredient.

After the curing phase, when the drying phase commences, the dry-cured meat will be ready once it has lost a minimum of 30% weight, ideally 35%+, I prefer.

Step 2 – Calculate Salt and Cure Ingredients

If you don’t have the accurate digital scales mentioned above, you’ll want to use the ” Saltbox ” method. You can get away with teaspoons if you trust their 2.5-gram approximation because it will depend on the salt!

I always prefer equilibrium curing because it’s flexible with time and precise in terms of the amount of saltiness. In a few decades of experience, I have reached a zero-fail level of salt curing.

The salt and other ingredient amounts are a percentage based on the total weight of the meat.

For example, 20 grams of salt per 1,000 grams of fresh meat – 2%

Most recipes are between 2.0% and 3.0% depending on salt taste preferences.

Weighing ingredients is a much more accurate approach to meat curing or cooking. (For example, a cup of salt may vary versus 100 grams of salt).

Based on my preferred saltiness, my preference for whole muscle meat curing is often 2-2.5% total salt to the total weight of the piece of meat I am salt dry curing.

I’ve a very popular equilibrium curing calculator page on this site – here is the link.

This percentage of salt includes (pink) curing salt, mentioned above.

You should be careful with the amounts of sodium nitrates and nitrites. They are very small and are included in the total salt you use.

For example, the target salt total is 2.5%

2.25% is sea salt, and 0.25% is pink curing salt

Pink Curing Salt or other similar types – Number 1 is for under 30 days of meat curing projects from start to finish. Pink Curing Salt number 2 is for over 30 days of meat curing projects from start to finish.

For more on pink-curing salt I wrote an article about it here.

Step 3 – Combine and Make Salt Cure Uniform

Using a Mortar and Pestle or a Spice Grinder, I can make the salt cure mixture more uniform and finer. I prefer it nearly powdery because this allows the salt to distribute more effectively across the meat.

Step 4 – Apply Cure to Meat

When it comes to equilibrium curing, it’s important to ensure all the cure is put onto the meat. I do this in a mixing bowl or a Ziploc bag.

Step 5 – Place Cure and Meat into Bag

Vacuum Packed Bags for Curing

Zip Lock Bags

When using a Ziploc bag, the best technique is to squeeze as much air as possible.

Step 6 – Place in Fridge and Fully Cure

I like to use the thickness of a meat muscle piece to calculate the time needed for equilibrium curing – an extra 1 to 2 weeks doesn’t matter.

25mm/1″ thickness = 4 days (this is conservative, but has never failed me)

Therefore, 2″ thick/50mm = 8 days (up to 22 days is fine also)

Adding Aromatic Spices before Drying

Now would be the time to add another layer of flavor on the outside; you can do this by making a spice blend.

Black pepper crushed at this point can also help the anti-bacterial protection because it has antibacterial properties.

Optional Casing

I included this as an optional step because it depends on the project. I usually do a regular fridge dry-cure project; I use muslin because it helps the exterior not dry as fast and go hard.

I have found that the cured meat can dry more evenly, I wrap or in case it. It seems to help hold in the moisture and prevent it from drying out as much.

I like to use butcher’s twine to squeeze the cured meat, which can help the drying process more. If you tie it uniformly, it is also quite aesthetically pleasing.

There are also many types of casings and bungs, which are intestines or stomachs of animals that work as well. See the pictures below.

Hang/Drying Meat

Now that the second phase occurs, we shall dry the meant once it is fully salt-cured until the target weight has been achieved.

2 pounds / 1 kilogram of meat, may take approximately 3-6 weeks

4 pounds / 2 kilograms, may take approximately 4-8 weeks.

The less fat on the exterior of the meat, the faster it dries. The leaner the meat muscle you are using, the faster the drying.

Step 7 – Remove from Bag and Hang

With equilibrium curing, the rinsing of the meat is not so essential.

I use a small square piece of cardboard, to record the:

- Description

- Starting weight

- Finishing Weight (70% of Starting)

- Date of Hanging

Using a chopstick or narrow knife, make a hole for the butcher twine to go through and make a loop for hanging.

I’ve measured a piece of wood to fit into a kitchen fridge shelf holder and some hooks. I can then hang the meat at the back of the fridge so it doesn’t touch anything. This is for a DIY fridge with the controllers and components to create a suitable environment.

The same wood/hook method could be used for smaller salt dry cured meat projects in your regular kitchen fridge also.

Of course, there are many ways of creating this hanging system.

An expandable shower/closet rack is a unique technique I invented also:

Hanging the cured meat helps to dry it and avoid contamination from any surface.

Step 8 – Weigh Periodically Until Target Weight Achieved

Now it’s time to use most of your senses – visually observe, smell, and squeeze it.

Remember how we recorded the 65-70% weight at step 1 and you wrote the finished weight on the card before hanging.

Now we keep weighing until that has been reached.

Most fresh meat has some form of ‘beneficial’ bacteria on it. Often, the hung meat will ‘bloom’ mold—hopefully the good kind! This is also where your nose will guide you. The right mold has a powdery, savory smell, almost mushroom-like (Penicillium nalgiovense).

Although smell is the most helpful way, I’ve written this article on mold to guide those new to meat dry curing.

Recipe Variations

I’ve created some classic salt dry cured recipes using this’ how-to’ method.

Each recipe has my built-in auto calculating equilibrium curing for the cure mixture.

What to Serve with Salt Dry Cured Meat

Charcuterie boards are a popular appetizer starter; a quality baguette or sourdough bread works incredibly well.

Antipasti styles are classic, including marinated olives, bread, cheese, and cured meats. I’ve enjoyed antipasti in Italy, there are many variations – sometimes grilled courgettes, wild pork pate of Tuscany, and many others.

Tens of thousands of dishes are made across Europe with salt-dry cured meats. Like pancetta, salt-dry cured pork belly is a basis for sauces and pasta across Italy.

FAQs

How Long Does the Dry Cured Meat Last?

If the outside has not hardened, dry-cured meat will last weeks or months – it will continue to dry if uncovered.

If the meat is fully dry-cured, if you keep it in the condition it prefers, i.e., 70-80% humidity or 11°C/50°F, it has the potential for many months of storage, potentially years.

Vaccum packing is the ideal way, once mold has been removed with vinegar to store the dry cured meat in the fridge.

How Should You Slice the Dry Cured Meat?

Very thin, less than 1 mm. The best tool is a sharp knife on one side and an accurate deli slicer that can cut slices less than 1mm wafer-thin. It has a lot to do with technique.

What About the Mold on Meat When Drying?

Penicillin or powdery white mold on cured meats produces a specific type of pleasant smell. This is a good sign; it protects the meat from foreign bodies.

For an article I wrote about meat curing and mold – here is the link.

Storing Salt Dry Cured Meat

Vacuum packing is the most consistent method for salt dry cured meats. I’ve used this method for 4-5 years of storage, and keeping the cured meat in my regular kitchen fridge.

If the meat muscle has skin, it tends to provide a barrier to slow the drying. What I’ve noticed across Italy and Spain is that dry-cured meats are hanging in store standard deli temperatures for months on end. Remember, it’s preserved!

More Variations

Here are some other styles and ideas for flavor. The amount of spices is minimal, but it’s enough to create a complex, subtle flavor.

It can be helpful to make whole spices fine; that’s where a spice grinder can be helpful.

Salt and Spices for Different Meats

- 2-2.5% sea salt for equilibrium curing

- 0.25% pink curing salt No. 1 (optional)

- Farmed Duck – 1 clove, 1/3 cinnamon stick, orange zest, 0.5% pepper

- Beef 1% – garlic, 1% sweet bay leaf, 0.5% juniper berry

- Pork – 0.5% pepper, 0.5% juniper, 0.5% nutmeg

- Wild Red Game – 0.5% Rosemary, 0.25% juniper

How to Dry Cure Meat at Home (Equilibrium)

Equipment

- Weighing Scales For equilibrium curing 1 decimal place in grams as minimum.

- Mortar and Pestle / Spice Grinder For crushing the spices and salt to a uniform consistency.

- Meat Drying Area / Chamber Cellar, Shed, Wine Cellar, DIY Fridge Converison

Materials

- 1 meter Butcher Twine or Jute Strong enough to hang the meat whilst drying

- 1 piece Bag, Container for Curing A ziplock or vacuum pack bag can be most effective for the salt curing phase

- 1 piece Natural Casing, Muslin for Exterior Optional, can be used to regulate the drying. Semi-permeable, traditionally beef bungs (intestines) were used.

- cardboard Recording Starting and Finished Weight

Instructions

Salt Dry Curing Phase

- For every peice of meat to cure, weigh meat and rcord both starting and finishing weight (70%).

- Calculate salt and Cure ingredients – use equilibrium method

- Combine and make salt cure uniform – finer cure will be easier to disperse on meat

- Apply cure to meat – cover all sides evenly and in crevices.

- Place cure and meat into bag, remove air out of bag.

- Place in fridge and fully cure, approx. 3-4 days per 25mm/1" thickness

Drying Phase

- Remove from bag and hang in appropriate drying area/chamber. Using S hook, or other method advised above.

- Check meat regularly for mold and visual/smell signs, leave haning until target weight achieved (minimum 30% weightloss from starting weight)

Notes

- Humidity and Temperature: For ideal drying conditions, maintain a slightly humid (65-80%) and cool (50-60°F/10-15°C) environment.

- Equipment and Ingredients: Quality meat, accurate scales, salt and spices are essential for successful outcomes with dry curing.

- Air exchange or airflow – some is needed

Feel free to leave any comments or questions, I’m always replying and happy to advise.

Tom Mueller

For decades, immersed in studying, working, learning, and teaching the craft of meat curing, sharing the passion and showcasing the world of charcuterie and smoked meat. Read More