I’ve seen many different designs for meat curing chambers, from Prosciutto Parma Ham factories in Italy to many DIY home curing chamber conversions—5 so far.

The design factors used are all very similar, and you can replicate these things at home or buy an ‘out-of-the-box‘ solution as well.

Since charcuterie and meat curing involve some craft and a sprinkling of science, it is probable that any non-commercial design will need some tweaking and testing to achieve the right conditions.

But really, it’s all about promoting an environment that grows good bacteria to prevent the meat from spoiling. Secondly, to have a cool temperature and a high enough humidity so that the meat doesn’t dry too fast on the outside, before drying on the inside.

Oh yes, and then there is airflow and exchanging fresh air.

In Summary,

To design a meat curing chamber you need to balance temperature (50-60°F/10-15°C), Humidity (70-80%), and Airflow. Humidifiers, Dehumidifiers, Domestic/Commerical Fridges, Fans, and Controllers are needed to reach the desired conditions.

Designs for a Meat Curing Chamber

Temperature of 50°F or 10°C has always been targeted if you want slightly less mold growth, its at the lower end for the white good mold to florish. Up to 60°F/15°C – although I’ve dry-cured meat slightly higher than this.

Humidity is not over 80%; more design factors will be needed later on.

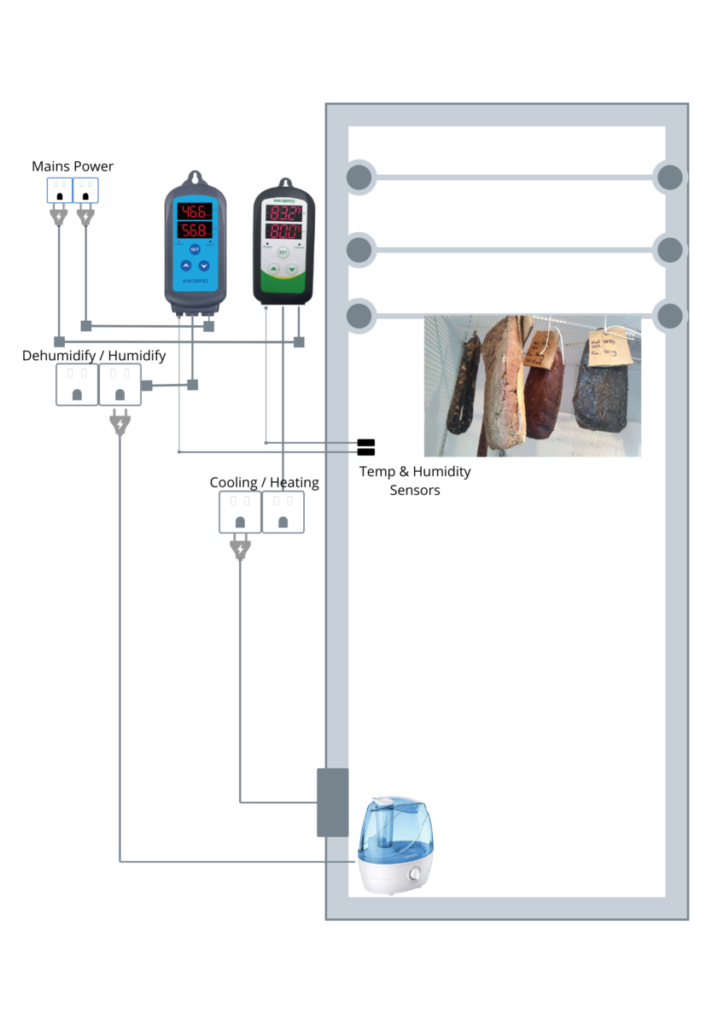

This is one of the DIY designs I have in my pdf curing chamber design book you can check out.

I’ve used second-hand fridges that are frost-free and older non-frost-free. It’s been easier to design a fridge with a frost-free cycle because it cycles a lower average humidity. Therefore, you can sometimes get away with just a humidifier with a controller to turn it off and on.

Out of the five fridges I’ve designed, all have needed both a humidifier and dehumidifier, however.

UPDATE:

Some more modern fridges with airflow from the ceiling can be ideal for converted, although controllers will still be needed for temperature and humidity (LG fridges work, here is more reading on that fridge here – LG LRONC1404V.)

DIY Fridge Conversion

The most common way home curers create the environment they need is still converting a fridge. Depending on location, some people do end up having a favorable area around the time that may have the right temperature and humidity for several months of the year.

A regular kitchen fridge operates at around 32° to 40°F or 2° to 5°C.

20 to 40% humidity is quite common with most compressor fridges.

Kitchen Compressor Fridge

A temperature and humidity control is needed to sense the conditions inside the fridge. The controllers then turn on/off a humidifier and the fridge’s compressor.

Sometimes, the inbuilt fan is enough to circulate air, but it depends on the fridge’s design. There are many variations between fridges, but generally, a hole will be needed—with a filter/fan installed for extraction and possible inflow, too.

Making holes in fridges has its challenges. Cooling pipes are often embedded through the foam-filled insulation. I’ve hit a pipe once, but due to the cost of the fridge, I ended up getting it picked up for metal scrap.

I’ve been reviewing a small-format dry-aging and dry-curing fridge from SteakAger. See the bottom of the page for a link to more info.

Mini Fridge

Small fridges can also provide the same conditions, but because they are in tight spaces, smaller equipment, such as humidifiers or sometimes dehumidifiers, needs to be used.

However, the same outcomes can be achieved by using a compressor fridge.

If the fridge piping/coolant plate is exposed to the back of the fridge, this can sometimes lead to a more straightforward conversion IF there aren’t any pipes going through the side walls.

Wine Cooler Fridge

There are thermoelectric coolers and compressor coolers. Some compressor coolers have a secular system in which the evaporated condensed water is heated and the humidity is pumped back into the wine chamber.

This may potentially be a suitable system for converting into a meat curing chamber, however, I have not tested it so cannot comment on it.

Natural Dehumidifying Effect

Some compresses have a natural dehumidifier, which can be beneficial when designing a meat curing chamber, as mentioned—frost-free generally.

Natural Environment – Shed / Cellar

If you literally have some environmentally conducive place around the property, which is protected from bugs, has some airflow and get roughly to this temperature and humidity.

You can, of course, try and dry the meat; outcomes can vary. However, smaller cured meats, less than 1/2 pound, can be dried in 1-2 months. Whole muscle is a lot simpler and easier to produce than dry-cured salami.

Home Build vs Store-Bought Design

Similar equipment can be used for a commercial curing chamber, the controller systems, which would be hardwired to commercial humidification (here are some DIY humidifiers I wrote about), and dehumidification.

Commercial compressors would be used. The moisture that may be created by the calling compressor system would need to be assessed.

The challenge is always how airflow/temperature changes the moisture, so the balance needs to be reached.

To be honest, a 10% temperature or humidity swing has never caused any issues with my meat-curing fridge designs.

‘Out of Box’ Solution – SteakAger Pro 40

Set and Forget for Dry Aging or with a Humidifier Accessory—they sell Dry curing, too. A 15% humidity range has left things a little drier than I would like.

But as I write this, it’s 65% less expensive than the $3k dry-curing small-format fridges.

But the old trick is to vacuum pack the cured meat once it has reached your target weight loss (30-45%). Then, leave it for 1-2 months for your normal kitchen fridge to equalize.

UPDATE

In recent years, a friend bought a Stagionella double-door commercial fridge for $10k USD. I’ve been teaching him how to dry cure meat. It truly has a plethora of options when it comes to air exchange, air flow, staging the drying process, vapor flavoring, and a lot more. After three years, we are still learning how to calibrate it optimally.

Here is a link to the DIY gear I’ve put together on another page.

Here is a long post I wrote about building a curing chamber.

I also wrote about dry curing small bits of meat in a regular kitchen fridge.

I could give you a list of things I was making in a huge double-door fridge I converted, not just for dry curing/fermenting cured meat. It was a commercial Skope fridge which produced many projects.

I used it for:

- Growing Oyster Mushrooms

- Fermenting Beer, Wine, and low wines for Distillation

- Drying Vegetables and Herbs

- Hanging Dry Aging, Wild Meat I had Harvested

Of course, there was a thorough cleaning and sterilizing before/after these various projects.

Design Criteria

So, let’s go over the most important factors.

- Moisture (Humidification)

- Cool Area (Temperature)

- Airflow

If you use a fridge, shipping container, wine cellar or any other suitable area – here are the parameters you should look for. Specifically for salt dry curing meat – either whole muscle or dry cured salami

Moisture (Humidification)

Depending on the stage of making cured meats, the moisture may need to be 90% or down to 60%.

I’ve learned that there is a step in prosciutto commercial dry meat curing, which happens after the salt cure is added – equalizing.

This is done to make the salt uniform throughout the meat. It is done nearly at a regular fridge temperature but with high 90% humidity.

For the home cure, this isn’t really as important, and you can set a 70 to 75% humidity and achieve most salumi projects or dry-cured meats. If you use an equilibrium curing or brining technique, it’s also due to large 30lb/15kg pieces of pork leg.

Controlling the humidity to keep within a range is somewhat important, and saying this, meat curing has been done in the natural environment very often over the ages.

When I was getting a personal tour of a Parma Prosciutto factory owner (https://www.slega.it/), Mr Borcini said after three months of a controlled environment for the Parma ham pork legs.

Including the equalizing phase.

The Windows were either open or closed depending on whether it was raining, and the natural breeze from the nearby Po River was really the moisture source.

As you can imagine, there would have been some large variations. I will note that the skin on the pork leg protects it from drying too fast.

Using natural or synthetic casings can mimic this partially, but pork skin is thick!

Cool Area (Temperature)

50° to 60°F or 10° to 15°C – these are the temperature ranges that are generally needed for meat curing.

Airflow

It is important that there is enough airflow to exchange what is in the chamber. I’ve known folks who just open the fridge door every day, but I was looking for slightly more hands-off designs.

The air does not need to be fresh all the time, but it should be cycled on/off.

Fixed or variable fans on timers or attached to controllers can also be used to achieve this. I’ve often found that 10-15 minutes a day can be enough. However, it also depends on how full the fridge is with high-moisture cured meat!

How do I deal with unwanted mold in my curing chamber?

Not all mold is beneficial for meat curing. White mold (Penicillium nalgiovense) is generally desired, but green or black mold should be removed. You can wipe down affected areas with vinegar or a saltwater solution. Some airflow and humidity control help prevent unwanted mold growth.

What should I consider when scaling up from a home setup to a commercial curing chamber?

Scaling up requires more space and reliable equipment, such as commercial-grade humidifiers and temperature controllers. Air circulation becomes more critical in larger chambers, and the capacity to maintain uniform conditions throughout the space must be carefully planned. Additionally, food safety regulations and local health codes must be followed. Designed an area that can be clean regularly is key also.

How can I cure different types of meat in the same chamber?

If you’re curing different meats, like pork and beef, consider each’s humidity and airflow needs. For example, salami may need slightly higher humidity than whole-muscle cures like prosciutto. Curing both in the same chamber is possible, paying special attention regularly is key

What are some tips for long-term maintenance of a DIY curing chamber?

Over time, condensation buildup and mold can affect equipment and the chamber’s surfaces. Regularly cleaning fans, controllers, and humidifiers is essential for consistent performance. Also, check seals and insulation to maintain temperature and humidity without excessive energy use.

Can I use a curing chamber for other fermentation projects (e.g., cheese, beer, or vegetables)?

Yes, curing chambers can be used for other fermentation projects like aging cheese, fermenting beer, or drying vegetables. However, each product has specific temperature and humidity requirements. For instance, cheese aging might require a slightly cooler temperature and lower humidity than meat curing, so be prepared to adjust settings accordingly.

Tom Mueller

For decades, immersed in studying, working, learning, and teaching the craft of meat curing, sharing the passion and showcasing the world of charcuterie and smoked meat. Read More