When it comes to curing meat, especially dry-cured meat, over several months or more, interpreting mold growth is one of the more challenging hurdles I’ve encountered since I began learning the craft several decades ago.

The beneficial mold, once nurtured in a conducive environment, will then assist in the more even drying of the cured meat, more on this later.

Once you become familiar with the beneficial types of mold or develop them in your drying area, they eventually start to grow naturally if conducive conditions are present.

I’ve found it easier to inoculate new dry-cured meat in the drying chamber.

When I started dry-curing meats, I didn’t use any starter culture, which is one method for inoculating either the meat or the dry chamber (or both) to create the right environment at the start.

I followed the natural path and was willing to let nature decide whether the project progressed. It was often ‘blooming’ naturally, though I’ve now done it to dozens of drying chambers with some experiences to share. This comes from the meat, although it is invisible to the naked eye until it has grown.

Dry-curing meat has been practiced for thousands of years. Hundreds of years ago, it was nurtured regionally in Italy, much like sourdough starter cultures.

Common sense, logic, and trusting your instincts about whether the food is edible will help significantly when learning about the beneficial mold for homemade dry-cured meats.

Examples of Beneficial Mold on Cured Meat

I’ve included many examples of the mold in various projects below to help visualize it.

You’ll notice that sometimes a casing is used, and sometimes it isn’t. Casing slows drying, making it even for many whole-muscle meat curing projects.

Purpose of Beneficial Mold

This helps regulate the drying process of the cured meat

It also gives it a layer of protection. For some, the flavor is another factor that adds another level of complexity.

The goal, often, but not always, for dry-cured meat projects is to develop a good covering of powdery white penicillin mold outside the dry-cured whole muscle meat or dry-cured Salami to regulate the drying process.

If no mold is present, the drying on the exterior of the cured meat can be significantly drier than the center. The goal is always to dry the meat slowly, so this is ideally avoided. However, most home meat curers will struggle with this. It’s often called ‘case hardening’.

If the exterior becomes too dry, it can prevent moisture from dissipating internally. I’ve never had this occur.

The mold you want for your dry-cured meats can either naturally bloom or be introduced from a commercial culture, which is bought and kept frozen to keep the cultures alive.

It can be a purchased starter culture that you then inoculate with the cured meat, and, if desired, the chamber with a few sprays.

For many dry-cured meat projects, the drying phase lasts more than one month. Typically, it takes a couple of days or a week to see mold blooms on meat, depending on where it was hung (e.g., in a chamber or cellar). Cold-smoked meats will often have less or no mold growth due to the antifungal properties of smoke.

The general environmental factors that promote beneficial mold growth are temperature, humidity, airflow, existing mold culture (which may be present on the meat but invisible), and the amount of light (less light is preferable, as it can cause fat rancidity over time, without the use of light bulbs in the chamber).

Main factors being:

Temperature – 50-60°F / 10-15°C

Humidity – 70-80%

Other recipes, such as Calabrian pancetta, are covered with pepper and chili/pepperocino. External spices are used to deter the growth of mold.

Peppercorns and black pepper have antibacterial and antifungal properties.

Flavor of Beneficial Molds

The taste and smell relate to the type of umami or savory flavor.

One of my friends, whom I taught how to dry-cure meat, loves the flavor of the white powdery mold that grows outside his wild pig guanciale.

A significant amount of complexity can occur with the smell of Salami or a whole-muscle piece of charcuterie as it develops; this is why I find this craft so fascinating.

Here is a video I made about Salami cured meats and mold:

Natural vs. Lab-Created Mold

Supposedly beneficial mold is on many meats and foods. This is why I’ve had several naturally occurring types of drying fridges create species similar to the common Penicillium nalgiovense.

Depending on your environment, your piece of meat may have a chance for naturally occurring penicillin to start growing on it. I’ve done this several times over the years with new DIY meat curing chambers I’ve put together.

However, this is not guaranteed.

Commercial producers of dry-cured authentic Salami, which takes months, not the tangy acidic stuff made in a few days, often use this culture to ensure consistent outcomes.

They buy stuff and inoculate the salami or whole-muscle meats themselves.

Mold 600 – Bactoferm

Home charcuterie makers and many other producers utilize CHR Hansen Mold 600 for inoculating whole-muscle meat during curing.

There are plenty of starter cultures, but many perform a similar function for Salami: acidification (a key tool for preserving Salami and creating good outcomes). That’s more for international acidity increase (another way to safeguard the Salami).

Mold 600 is more concerned with the exterior of the meat or casing during drying.

I have it sitting in my freezer now. You can’t get it in every country, but most countries in the Western world do. It probably has other names.

Guys have contacted me through the blog about trying to ‘scrap’ commercial traditional Salami they buy to inoculate their DIY curing chambers!

I take half a teaspoon to half a cup of water when using it. The water should ideally be distilled, but filtered water has also worked.

Then, after giving it a shake, you leave it on the bench for eight hours and spread it in the chamber onto cured meat. Within a few days, you should start to see the spores of white mold developing.

Here is a link to bactoferm Mold 600 on Amazon.

Beneficial White Molds Will Age into Green Molds

Many people talk about powdery mold, but when you start learning more about dry-cured meats (here is a page on all the guides on this site), you’ll notice that at first, you might get fluffy mold.

But really, underneath that fluffy white mold is powdery mold. It’s just the way that it grows.

Then, as the mold ages, a green mold related to the spores of the white penicillin mold develops. What I’ve noticed is that the smell of this green mold is pleasant.

The above picture shows well-developed green mold in a commercial environment in Lavasi, Calabria, at the bottom of Italy.

Removing Mold From Cured Meat

Ways of Reducing Mold on Cured Meat:

- Acidity (vinegar)

- Cold Smoke

- Lower Humidity

- Lower Temperature

These methods can be helpful when drying meat and preventing excessive mold, which is beneficial in some instances. I’ve visited commercial Artisanal producers, often wiping and brushing away the excess mold.

If there is excess mold, a soft bristle brush is often used first to remove most of it.

The easiest way to remove white mold or any other type of mold from meat is to use vinegar’s acidity. White vinegar works effectively, but flavored vinegars, such as malt or red wine, are also suitable.

It’s not noticeable, I’ve found, when wiping off the vinegar in terms of flavor.

A diluted 50:50 mixture of vinegar can also be used. Wiping with a rag or cloth will remove most of the mold. Then, hang the meat again to dry.

If the mold is excessively growing, a soft brush can also be used, provided it is sterile.

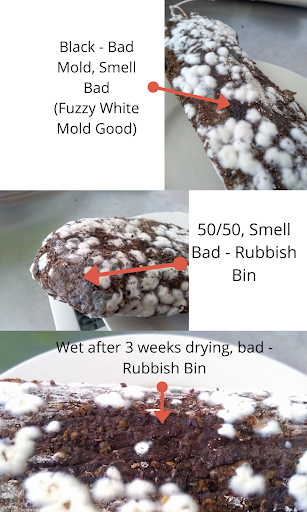

I have had some funky molds going on. Here are a few examples of things that are neither good nor bad, but rather what you want to avoid.

When you’re using no casing and going natural, which I often do because I like to see exactly what’s going on, using vinegar and wiping the mold off, or even giving it a blast of cold smoke for a few hours, can help knock back some of this unwanted, multi-colored mold.

Often, with a homemade drying chamber, using a fridge and thermostat controls, you can tweak the environment to benefit the balance of the mold. Here is another article I wrote on drying chambers

Unwanted Mold – Black

However, the black mold in the center is one of two pieces I have thrown out over a few decades of making dry-cured meat.

There is a particular ‘off’ smell and a moist-looking black mold that I’ve encountered only a couple of times over the past few decades: the ominous black mold.

It looked slightly translucent and was likely caused by some exotic spices I used. I am unsure whether this was a factor.

Spices like star anise, coriander, cumin, and galangal were used. And there was this mold patch of what I would consider very unwanted off-mold.

The smell was very off-putting, and my olfactory (sense of smell) system instantly said it needed to go straight into the rubbish bin.

We have an evolutionary, naturally developed ability that may help us determine whether food is safe to eat. Smelling and looking at it closely can be helpful.

I often get close to my homemade dry-cured meat with my nose and sniff vigorously. This usually gives me an indication of how the beef is progressing.

Put differently, if you have any doubts about anything you’re making, it’s not worth getting sick from, and you should always be on the side of conservatism. After decades of making dry-cured meats, I’ve only thrown out meat twice.

I’ve also noticed that when I had a dry curing chamber power cut, it reset to a fridge temperature. The hanging Hungarian Salami did have some white mold, as I hadn’t noticed the incorrect drying temperature.

I changed it back, and after a day, the white mold had disappeared (the temperature was back to approximately 12C or 55F). Lower temperatures can be used to eliminate unwanted mold.

FAQS

Can you eat mold on dry-cured meat?

If it is beneficial mold, it is edible – often it is a mushroom with an umami flavor.

What is the white powder I see on my cured sausage or Salami?

That’s likely beneficial mold, often Penicillium nalgiovense or similar strains. It’s intentionally added or can naturally develop during the drying phase. It can help with flavor development, prevent the growth of harmful bacteria, and control drying.

Should I be concerned if I see green or black mold?

Yes, you should be concerned. Green can potentially be a well-developed, beneficial mold. However, black mold may signify spoilage and potential mycotoxin production. It’s best to discard the affected meat.

What causes undesirable mold to grow on cured meats?

Factors such as salt curing or spice mix, improper humidity, inadequate air exchange, insufficient airflow, or temperature fluctuations.

How can I prevent unwanted mold from growing on my cured meats?

Maintaining control over temperature and humidity during the drying phase. Using proper starter cultures and ensuring good hygiene during the process also helps.

What does “blooming” mean in the context of mold on cured meat?

Blooming refers to the healthy and even growth of the desirable white mold on the surface of the cured meat.

How should properly molded cured meat smell?

It should have a pleasant, slightly earthy, and characteristic aroma of the meat and spices, with mushroomy, umami, and savory scents.

What should properly molded cured meat feel like?

The surface with the white mold should feel dry and slightly powdery to the touch. Slimy or sticky textures are signs of spoilage.

How should I store cured meat with mold?

Store it in a cool, dry, and well-ventilated environment, ideally within the temperature and humidity ranges recommended for that specific type of cured meat. For longer-term storage, you can use vinegar or acidity to clean off the mold, let it dry uncovered in the fridge, and then vacuum pack.

Where does the beneficial mold come from?

It’s either naturally present in the curing chamber environment or, more commonly, introduced as a starter culture, after curing, during fermentation, and before or during drying.

Are there different types of beneficial mold used in curing meat?

Yes, Penicillium nalgiovense is the most common, but other strains, such as Penicillium candidum, may also be used.

How do commercial producers ensure the right kind of mold grows?

They use controlled environments with specific temperature and humidity levels and introduce specific starter cultures of beneficial mold. The existing drying environments often harbor beneficial molds as well.

What should I do if I’m unsure about the mold on my cured meat?

When in doubt, it’s always best to err on the side of caution and discard the meat. Your health and safety are the priority.

Tom Mueller

For decades, immersed in studying, working, learning, and teaching the craft of meat curing, sharing the passion and showcasing the world of charcuterie and smoked meat. Read More