Salami comes in many more forms and styles than people think. It’s not only put into one category. This article explains all the different types and clarifies them in detail.

Uncooked salami is cured, sometimes fermented, and dried. Depending on the process, this cured style may also be cold-smoked. Cooked salami is heated to an internal safe-for-eating temperature through hot smoking, steaming, or baking.

Here’s a table to clarify all the different types of salami:

| Type | Description | Volume | Length of Time to Produce |

|---|---|---|---|

| Uncooked Dry Cured | Salt-cured, and dried (sometimes cold smoked) | low | 3-20 weeks |

| Uncooked Dry Cured Fermented | Salt-cured, fermented acidification, dried | low | 3-20 weeks |

| Uncooked Salt Cured Fermented Rapid Acidifying | Salt-cured, fermented, rapid acidification -commercial | high | 3-7 days |

| Cooked Salt Seasoned Hot Smoked | Salt seasoned, cooked, hot smoked to a safe internal eating temperature, low temperature cooking | low/high | 3-24 hours |

| Cooked Salt Seasoned – Baked | Salt seasoned, cooked to a safe internal temperature at low temperature, so fat doesn’t melt | low/high | 3-24 hours |

Salami Cooked and Uncooked

It’s not that straightforward, but I will explain the topic below.

Salami Varieties

If you live in the Western world, you are accustomed to the classic “hard” type of salami that you’ll find in the supermarket. When squeezed, it has a firmness that cooked salami (I wrote about salami and keto in detail here) doesn’t have; rapidly acidified salami also has a softness.

This is often a salami that is first salt-cured, with a higher temperature and a moist fermentation stage.

Then, there is a drying stage, where a certain amount of weight loss occurs.

Other names for the salami are Genoa, pepperoni, or picante.

The least costly salami I can buy at a supermarket often has a soft texture, almost like a smoked ham in the delicatessen section. This is due to the rapid acidification mentioned in the table above.

Hard salami (cut and whole salami storage is also different) gets hard because it has lost weight during drying after being cured and often fermented, a salt curing and drying process.

Uncooked Salami

This salami style is uncooked because it has been made safe using salt to slow the water activity, making it hard for unwanted bacteria to survive.

It is often fermented between the curing and drying stages to lower the pH or increase acidity, which also makes it less appealing to unwanted bacteria.

It is uncooked because it is dried and fermented to the point where it is preserved. “Ripening” is another term used for the drying process.

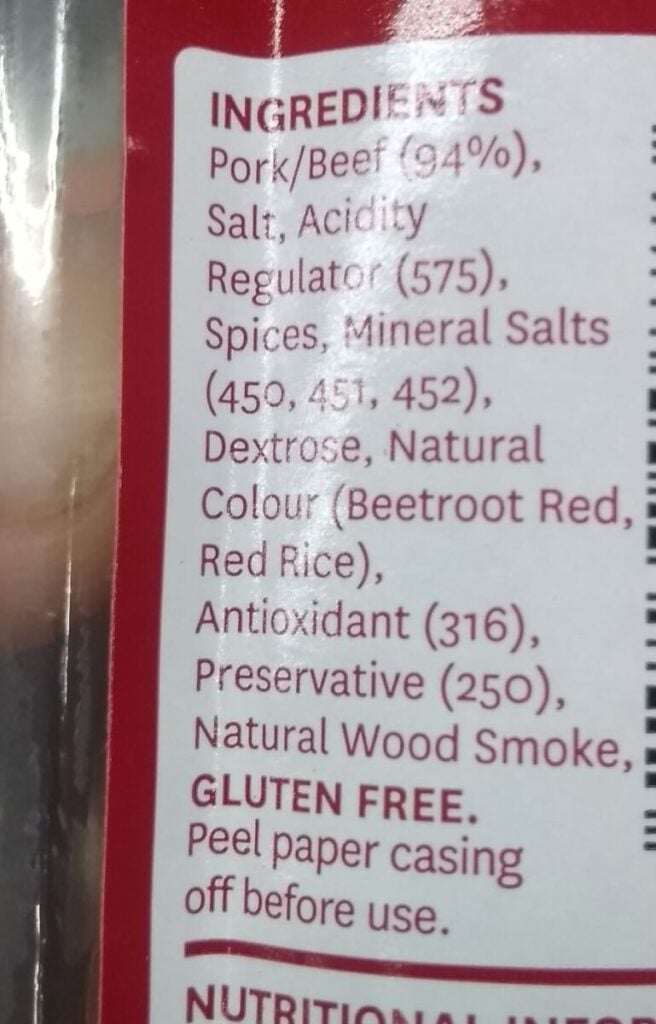

Curing meat (cured sausages is another way of saying salami) involves adding salt, although it is sometimes confused with nitrates or nitrates added as one of the ingredients. Since this additive contains approximately 90% salt and 10% sodium nitrate and nitrite, depending on whether it is under 30 days or over 30 days, a versions known as number one and number two pink curing salt which have many other names (instacure, Prague powder etc.).

Overview of Cooked Salami

These are often hot-smoked salamis, found in many parts of Eastern Europe, such as Kielbasa or Kohlbasa (with hundreds of variations). As mentioned above, less is used because you don’t need as much as when making the dry-cured all-fermented salami.

This salami style is often cooked at a much lower temperature than the meat, since it can keep the fat from melting or rendering. At the same time, the internal temperature of the meat reaches the minimum safe cooked temperature.

Salami Curing Techniques

Salt Curing

As mentioned above, salt is the primary method for curing meat.

Mold Growth Externally

External fermentation can be included in the curing process. Certain types of starter cultures help create a breathable mold that regulates the external drying of salami.

I have used these types of mold cultures. One of them is mold 600, a typical commercial mold for uniform beneficial bacteria externally.

Fermentation Internally

I have used many different types of starter cultures for flavoring and preservation. In a broad sense, you can put these into two categories: fast or slow fermentation.

You may be familiar with salami’s sour or tangy flavor, which is produced through a fast fermentation process. Slow-fermented salami often has only a very subtle tangy, sour taste (I wrote in detail about the unique taste of salami here) due to internal acidity changes.

Exploring Dry Curing Methods

Not all salami is dry-cured. As the table above shows, rapid acidification is used to quickly make the meat ham salami style, a fast manufacturing process.

As opposed to the multiple months it takes to create traditional artisanal styles.

Fermentation in Artisanal Salami Production

After the salt, spices, and possible nitrates are added. The starter cultures are sprinkled into a small amount of clean filtered water and allowed to turn blue slightly.

Starter cultures are added and mixed into the meat mixture.

Depending on the culture, temperatures and humidity vary, but they are often around 85% humidity and 60 to 70°F (15 to 20 °C).

This process takes 24 to 72 hours, depending on the starter culture. The pH should drop to a minimum of 5.3 to be considered a safe level of acidity. Then, we move on to the drying stage with slightly lower humidity and temperature.

The balance comes from trying to dry the meat evenly and not having the outside dry faster than the inside. I have found that this is one of the significant challenges of making traditional salami.

Rapid Acidification Process

This process can often be completed within 3 to 4 days. One way to tell if the salami has been produced in this manner is by squeezing it; it will be soft.

Cooking and Smoking Salami

- Hot Smoking Salami (here is how to make salami in a smoker I wrote about)

- Cold Smoking Salami

Some salami you buy might be steamed or cooked to an internal temperature; this means it’s not preserved and has a shorter shelf life than the traditional dry-cured salami, which is hard and has lost moisture to maintain its texture.

Not all dry-cured meat is cold-smoked; this is true for some recipes. In central Europe, Germany often has a strong culture of beach-smoked salami.

Why are Salami types so Confusing?

All salami is made from minced or ground meat, seasoned with salt and spices. The confusion comes from whether the salami is cooked and hot-smoked or dried and fermented, generally. Some commercial large-volume salami is only fermented through rapid acidification.

Why use salt in Salami making?

Salt slows the water activity in the meat, which means unwanted bacteria find it harder to survive in the meat. Seasoning and flavor are also why salt is used.

Can I make Salami at Home?

Anyone can make salami at home with some basic tools, and for hot-smoked salami, it is more straightforward. For dry-cured salami, certain nuances are often needed to get consistent results, like binding and stuffing techniques, especially.

Feel free to leave a comment, always love to here your thoughts.

Tom Mueller

For decades, immersed in studying, working, learning, and teaching the craft of meat curing, sharing the passion and showcasing the world of charcuterie and smoked meat. Read More