This question completely depends on what country is answering this question.

The mysteries of ham and whether it is cured meat will be covered in this post.

Quick answer and a breakdown since ham varies a lot from place to place. Most people always say ham is smoked, and it is sometimes.

But I’ll tell you what, in the big wide beautiful world of hams, they come in hundreds maybe thousands of different flavors and types.

Since I make ham and study it I have also tried many varieties of ham across the world this is a subject I thought I would share what I learned over the years.

Making good ham at home takes a bit of time and effort, and most guys end up buying it, there is a big difference between the commercially made cheap ham and the good stuff for all varieties too.

So give you a simple answer and get into more detail about it.

Is Ham a Cured Meat?

Not all hams are cured meats since the USDA has a ‘fresh’ ham categorization. Fresh means not cured, in most other Western Countries in the world. Ham is all cured apart from the United States. In Italy, a Ham is Salt and Dried. In North America, it is fresh, cured, either dried or cooked and smoked.

The entire world sees ham as cured, apart from in the United States. There is fresh ham, it’s fresh uncooked uncured pork.

But to make it confusing in the USA – Whole fresh pork leg can be labeled as fresh ham

If you want to go super technical, here is fresh ham breakdown.

Popular Types of Cured Ham Variations in the World

| Type | Description | Country |

| Country Ham | 2-3 months, fast to produce, often smoked, sugar used for flavor in cure | USA |

| Parma Ham | 12 months to 60 months, no nitrates allowed, only ingredients salt & pork | Italy |

| Jamón ibérico | 18-60 months, black pug, fed acorns for flavor under oak trees | Spain |

| Dalmatinski pršut | 12 months aging/drying minimum, lightly smoked | Croatia |

| Westphalian Ham | Produced since them middle ages. acorn-fed pigs. | Germany |

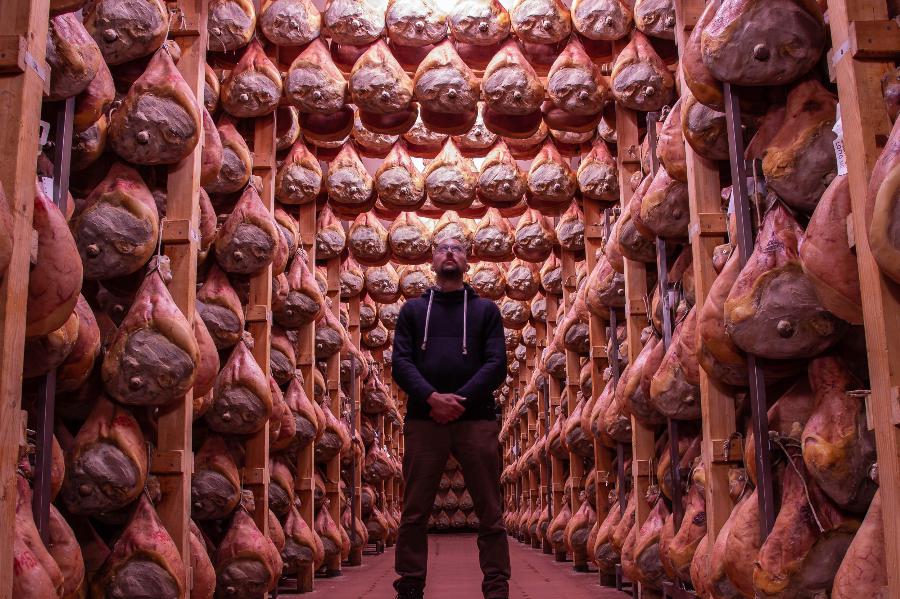

Prosciutto Parma Ham

It’s sweet, a little nutty and I could eat this stuff every day. I can’t say that about a lot of cured meats. It’s true bliss.

Jambon de Bayonne

Some of the Finest dry-cured ham of France. Black pig, has a distinct flavor and an awesome eating experience.

Jamón de Serón

There is a reason my brother could eat 5 plates of this super fare, more nutty and a deep crimson color from the Spanish black pig.

Schwarzwälder Schinken

Distinct beech wood and often juniper (conifer) smoked. If you like smoked dry-cured meats, this is something special. (Also check out Black Forest Ham, Schwarz Ham)

What is Cured Ham Meat?

- Dry Salt Rubbed

- Wet Brine Cured

- Injected with Cure Brine

It doesn’t matter which ham variety we are talking about, all hams have had salt used to cure the meat. There are different techniques for how the salt can be applied.

Unless you are in North America.

Using salt to preserve and intensify flavor, whether it’s applied via a dry-cured rub into the meat or mixed into brine with water, spices, herbs etc).

If every hand was made to the highest quality, it would take some time to make (longer than the market demands). The deeper more interesting flavors of ham get bypassed with Commercial shortcuts (more on this later too).

Like anything, it’s what you are with that counts, so for ham – the pork breed, feed & lifestyle will play a part often. Especially in regards to the dry-cured hams below like Iberico Jamon & Parma Prosciutto.

Due to our modern demand for fast food and fast profit, the traditional ham can now be made in one day with factory commercial equipment and ingredients.

These are all still cured hams (here is how to cure ham so it’s not overly salty) using salt. But many ‘shortcuts’ are used.

In contrast, dry-cured hams, especially those protected by law in Spain and Italy can take 1 to 5 years to be produced. This is another reason why they are one of the most expensive foods in the world. But that is just one style of ham.

Nitrates are often used to make sure no botulism has a chance to inhibit meat. It also adds a certain flavor and pinkish or reddish color.

Low-cost deli ham would be gray instead of pink without the nitrates that are added to it. Same with bacon unless there are trace elements of nitrites.

Salt Dry Cured Ham

Dry salt-rubbed or dry-cured hams are just applied straight to the ham in one session or multiple sessions. The salt is doing the magic of inhibiting the meat binding to proteins and slowing down the bad bacteria which would normally spoil the meat, and some other interesting effects.

This is a common theme in all cured meats, and the magic of salt is the quintessential cornerstone of curing.

Wet Brine Curing & Injecting

Whether it is injecting or submerging a ham in salty water brine, it’s another way of curing the meat or inhibiting the meat with salt, it takes a salt bath or gets pushed in with meat needle pumps.

Generally, you will find that the more water that’s involved in the process, the more watered down or lighter the flavor.

It’s a cost-cutting process because producers are also bulking up the weight of the meat, so instead of paying for meat you pay for water injected into meat. A cheeky modern approach towards companies is to make more money out of the ham.

I have heard that they also inject water into fresh pork and sell it like this. With chicken too, it’s called ‘plumping’ – here is a wiki ink

This site explains it well too. Always a good idea to read the pack or be an informed consumer!

Cured & Smoked Hams

After curing, some hams are smoked. If you go back a few hundred of thousand of years, I have even read about cold-smoking meat being used to around 300 years BC.

Cold smoking the meat carries anti-fungal and anti-bacterial properties, which was a way of helping make sure the meat had a better chance of being preserved.

Cold smoking is not as difficult as some people think it is, a lot of guys start out with cheese or nuts.

I love making dry-cured cold smoked bacon (yes cold smoking bacon is safe, I wrote an article about that here), finally found a recipe that I’m incredibly happy with too!

The important aspect of cold-smoking meat is curing the meat properly if you want to read about curing meat, here is an intro I wrote.

So basically you are applying some smoldering smoke from hardwood with low resin (often fruitwood is a good choice), the most important aspect is keeping the temperature low

It should be below 86°F or 30°C. Some types of meat start to cook above this temperature, cold smoking ham is generally done around 52 to 68°F or 10 to 20°C. Airflow and humidity are also pretty important when doing a cold smoking session.

An Example,

Probably the most popular type of Ham that is smoked is the country ham. In terms of production, this cured dry ham takes about 2 to 3 months to make.

Hot Smoked & Warm Smoking

Cooking whilst smoking ham is done as well after curing. Then there is a warm smoked ham. There is such a massive variation in regard to this.

The easiest way to explain it is the meat is wet brined and then cooked whilst being smoked. Similar to Low & Slow barbecue-style cooking/smoking at the same time.

How Cured Hams Are Made

Salt & Cured Hams

It’s the cornerstone of cured meats, you have to have salt for flavoring, preserving, and in some regards coloring depending on the minerals involved.

Effects of Injected Water into Ham

Commercially you will find a lot of hams are injected with water that is be mixed with salt sugar, nitrates, and phosphates.

Quality and the Price of Ham is directly related to the amount of injected water

Chapter 22, Page 462 Home Production of Quality Meats & Sausages

Phosphates Hold the Water In

Phosphates can hold the water inside the ham, so you end up getting a lot more weight initially. But this is a profiteering trick to bulk up and makes the ham seem bigger than it is, as mentioned above.

It’s different plumping and pumping meat to increase the weight vs. using ‘uptake’ calculation to figure out how much a wet brine has inhibited the meat for traditional cured ham.

Different Meats for Ham

- Turkey -cured

- Chicken – cured

- Beef – cured

- Pork -cured

Even though there are all these different variations, the process is still very similar. All of these are cured as well, you always start with the salt either in a dry aspect or brine being submerged or injected.

Categorize of Ham & How They are Made

- Dry Cured Hams ie. Dried not Cooked – Prosciutto, Serrano, Jamon

- Whole Cured Hams – Cooked ie. Berkshire Ham

- Pressed Cured Hams – Cooked ie. deli ham or luncheon

Some hams are smoked and some aren’t as mentioned, it all depends on the ham!

It all starts with salting or brining depending on the ham.

How ‘Dry Cured’ Ham is Made

Saturation or Equilibrium Dry Curing

The traditional way of curing meat was always the saturation method (link to article on this method) or sometimes called the saltbox method, you cover the meat and salt, maybe other spices if you want.

Then you leave it for one day per pound. Sometimes traditionally weight was also applied on top to help push & penetrate the salt-cure into the meat.

This is still kind of the way many traditional dry-cured hams are made like prosciutto (here are some prosciutto substitutes I wrote about) cured ham.

For smaller cuts of meat or muscle, equilibrium curing is a great way of working out the salt to be effective but also not overpowering the meat. You use a percentage of salt to the total percentage of the meat.

I and many thousands of meat curers around the world, use this technique for meat curing at home. Here is a post I wrote about this technique

So if you want to do this kind of stuff at home, you can make a DIY curing chamber – if you want to read more about this, check out this post I wrote.

Dry ham or brined an equalization stage happens in the commercial production after the salting for large whole-leg commercial hams.

To equalize the salt uniformly throughout the meat.

A high humidity area with a fridge is like a temperature.

Then the pork moves on to the drying stage which can take a few months to a few years. Often still in Parma, where Parma prosciutto is done, they use the natural favorable conditions to perform this drying process.

The dry Curing chamber is set at approximately 75% humidity and about 50°F/10°C or slightly warmer.

Depending on the ham, after dry curing, the optional smoking occurs. In Montenegro they produce Njeguški pršut, I visited a reputable ham curer.

They smoke the ham for like a month or more!

How Whole-Cured Hams Are Made

Smoked or Cooked (or partially cooked)

The brining in a salt-based solution and/or injection of the brine into the pork is often the curing process used.

One comment in a curing meat book highlights that commercial producers have to use shortcuts which the home curer doesn’t need to.

You’ll hear more about this and ‘tumbling’ the meat below.

Immersion in the brine can take 4-6 weeks, this is when the salt goes and does its curing work.

Injection of the wet brine is often use to rapidly speed up this process.

Drying or Smoking is used depending on the ham being produced.

How Pressed Cured Hams Are Made

This is going to be a lot of generalization here but here is an overview about pressed ham and how it’s made.

It normally has a shape that is unlike one of the muscles of the pig. It may be a rectangular or oval shape, which of course makes this a lot easier to slice.

This pressed ham may have come from lots of different parts of the pig, not just the leg.

Ham steaks are the same kind of thing.

Then you come to the idea of exudate, which is smashing up the structure of the protein enough so that it releases myosin.

Imagine myosin is a type of natural meat glue that binds together the meat. In the commercial production of this type of ham, this stage involved tumbling.

Phosphates are often used before tumbling to extract more myosin as well. The tumbling distributes, cure is made up of salt, phosphates, nitrates, sugar, and spices generally.

So this is how the meat is bound together and has that uniform look just like ham steak!

This is of course a kind of factory food production technique for speed and profit generally.

Then there is stuffing the meat into bags/nets to create those uniform shapes. Sometimes molds are used to get to a certain shape.

Simplest Cured Ham

Prosciutto Parma Ham

Ingredients for Parma Ham:

Salt, Quality Pork, Well-fed Pigs, Craftsmanship, History, Passion, Natural beneficial mold (Penicillin), Respect for Tradition, Favorable Environment, Official Government Protection

or just salt & pig.

Very much a product produced in larger quantities, which I saw firsthand when I toured a ‘Parma factory’ with one of the owners.

There are shortcuts in this industry as well. But on the whole, the Italian government certification agency is making sure quality aspects are followed during the process.

If you have tried this official Parma Ham, it’s something really special. But a completely different ham to the pressed cooked ham!

Here is a link to an official site all about Parma Ham

It is quite hard for me to call both these things ham. But if the ham is the use of salt to cure the pork – it’s a general term I guess that can be used for both.

Prosciutto Parma is the simplest in terms of ingredients. Even by international law, the name is protected. It has to tick a lot of boxes and come only from Emilia-Romagna in Italy.

Then a minimum of 12 months until the product is finished. The owners did highlight that they expect a loss of 2 to 3% of the 85,000 Parma ham they produce every year.

This is just part of the excepted losses, and this is why dry curing meats, especially in the traditional way is considered an art and craft.

But if you want to learn a little about the basics of doing it at home, check out this post I wrote.

Tom Mueller

For decades, immersed in studying, working, learning, and teaching the craft of meat curing, sharing the passion and showcasing the world of charcuterie and smoked meat. Read More