Add a starter culture to the ground meat: there are various cultural or traditional methods that can be used to ferment the salami and create the desired acidic environment.

Fermentation in dry-cured salami and whole-muscle cured meat can occur naturally from existing fermentable cultures that already exist in the meat.

How to Ferment Salami

Most Consistent Way to Ferment Dry Cured Salami

- Purchase Starter Culture (should come in a chill box)

- Keep in Freezer

- Rehydrate for at least 30 minutes with filtered water

- Add to Salami mixture after spices/salt

- Ferment at the specified time, temperature, and humidity

- Hang at Drying Temperatures for Salami

I’ve seen natural fermentation rooms in small factory salami and whole muscle cured meat facilities.

These are often at 68°F/20°C with humidity at 85%, according to my interviews, tours and research. 20 days are used to develop flavors and drop the pH naturally for certain whole-muscle dry-cured meats.

Just note that this is in a commercial, controlled environment, which is constantly being monitored.

Home production of cured meats and fermentation can create a more inconsistent environment.

I’m specifically talking about the fermentation stage, which decreases the pH level in the salami, producing a more acidic environment.

I want to talk about one of the crucial aspects of salami fermentation that gives it that irresistible tang and distinct flavor. And at the heart of this art lies the concept of pH levels.

I’ve done enough batches to ‘begin’ to learn the ins and outs of making dry-cured salami (here are some of the mistakes and lessons I’ve learned). I’ve used pH testing tools to highlight some aspects, and I’ll go over that, too.

During fermentation, the pH of the salami gradually decreases, resulting in a more acidic environment. This drop in pH is not just a chemical transformation; it’s a flavor revolution that transforms ordinary meat into a delectable treat.

For some cured meats, I’ve seen that they actually put whole dry cured meats that are not inoculated with starter cultures. They keep the cured meats at higher than drying temperatures with high humidity, similar to drying humidity approx 80%.

I will try and focus on the practical knowledge instead of the technical. This is how I understand the topic easier.

The Role of the Fermentation Stage in Salami

But what exactly is happening during fermentation?

It’s a symphony of microscopic life.

We use beneficial bacteria known as starter cultures. These incredible organisms work their magic and breaking down sugars in the meat and converting them into lactic acid.

Why is this conversion so necessary, you ask?

Well, it accomplishes two vital things: flavor development and safety.

The lactic acid produced during fermentation gives salami its signature tang and creates an acidic environment that inhibits the growth of harmful bacteria. It’s like a natural shield protecting our beloved salami.

Starter cultures with slow fermentation have less tang.

This is known more in Central European Countries, I believe.

Now, let’s talk about flavor.

Fermentation is where alchemy happens. The lactic acid, along with other byproducts of bacterial activity, interacts with the proteins in the meat, breaking them down and releasing various savoury flavors. The longer the fermentation, the more time these flavors have to develop and intertwine, resulting in a more pronounced and sophisticated taste profile.

Not all salami you buy will be produced like this; well, many aren’t produced how I do it.

Many commercial producers who do large-scale supermarket salami will use fast ‘pacification’ to make the meat ‘safe’; salt is included. It’s actually skipping the artisanal and traditional approach, which I am talking about in detail here.

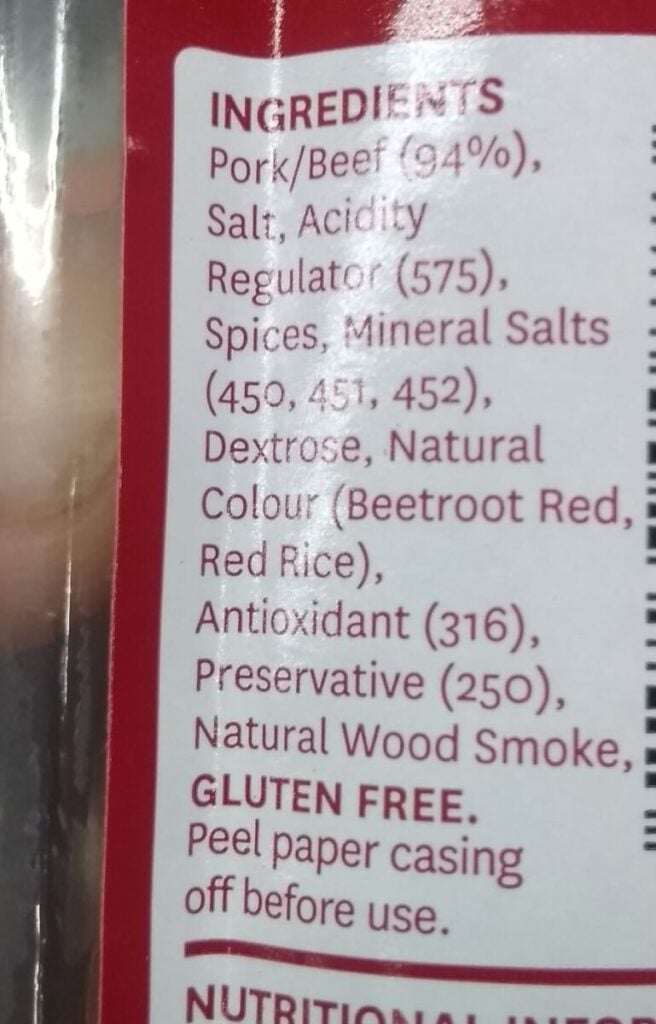

Here is a salami ingredient package of this fast-production salami product (I don’t think it should be labeled Salami, more like acidic cured sausage)

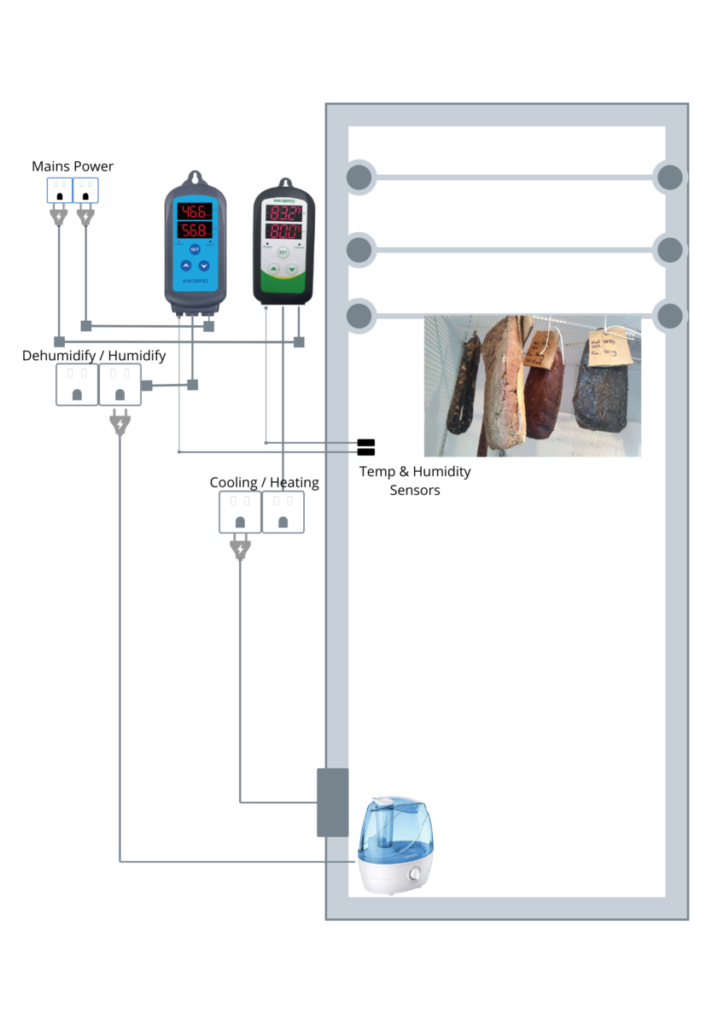

The fermentation stage requires careful control and monitoring

pH in Salami Fermentation

5.3ph is the Goal across nearly all formal dry-cured salami recipes I’ve seen.

pH, often called the “potential of Hydrogen,” is a measure of acidity or alkalinity in a substance. In salami fermentation, pH levels play a pivotal role in the development of flavors, the control of bacterial growth, and ultimately the quality and safety of the end product.

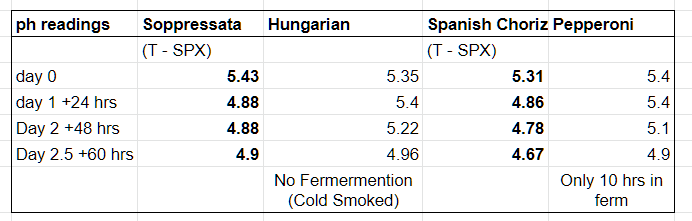

Here is a table of tests we did with salami we were making: 2 with starter cultures, 1 traditional Cold Smoked Small Diameter Hungarian Style, and 1 with red wine but not starter culture.

Factors Affecting pH Levels During Salami Fermentation

Starter Culture Selection

The choice of the starter culture can profoundly impact pH levels.

Different strains of bacteria present in the culture produce varying amounts of lactic acid, affecting the rate and extent of acidification. Selecting the right starter culture with specific acidifying properties can help achieve the desired pH balance and flavor development.

Temperature Control

Temperature plays a vital role in salami fermentation, including pH regulation. Higher temperatures tend to accelerate the fermentation process, leading to a more rapid decrease in pH levels.

Monitoring and maintaining the ideal fermentation temperature is crucial to achieve the desired pH range.

Humidity

The humidity level in the fermentation environment can affect microbial activity and pH levels. Optimal humidity provides an ideal environment for the growth of beneficial bacteria.

Fermentation Time

The duration of fermentation significantly impacts pH levels. A longer fermentation time allows for a more extended period of acid production, leading to a greater decrease in pH levels and more pronounced tanginess. Balancing the fermentation time is crucial.

Meat Composition

The meat itself can vary depending on the animal’s diet and muscle activity. Meat with a higher initial pH may require a more extended fermentation time to reach the desired acidity. Furthermore, the fat-to-lean ratio can impact the texture and flavor of the salami, indirectly affecting the perception of acidity.

Choosing the Right Starter Culture for Acidification in Salami

Here is a table below with an example of starter cultures and flavor indications:

| Starter Culture | Flavor Contribution | Commercial Names |

|---|---|---|

| Lactobacillus plantarum | Clean and mild lactic acid tang | F-RM-52, T-SPX, FLORA ST-DCU |

| Staphylococcus xylosus | Earthy, nutty, slightly sweet | F-RM-33, F-RM-35, FLORA ST-DCU-3 |

| Pediococcus acidilactici | Tanginess and acidity enhancement | F-RM-58, T-PC, FLORA PFL-AC |

| Staphylococcus carnosus | Savory, robust, meaty | F-RM-56, T-SC-100, FLORA ST-CU |

| Lactobacillus sakei | Mild flavor contribution, acidity | F-LC, LHP, FLORA PFL-SC |

Monitoring pH Changes During Salami Fermentation

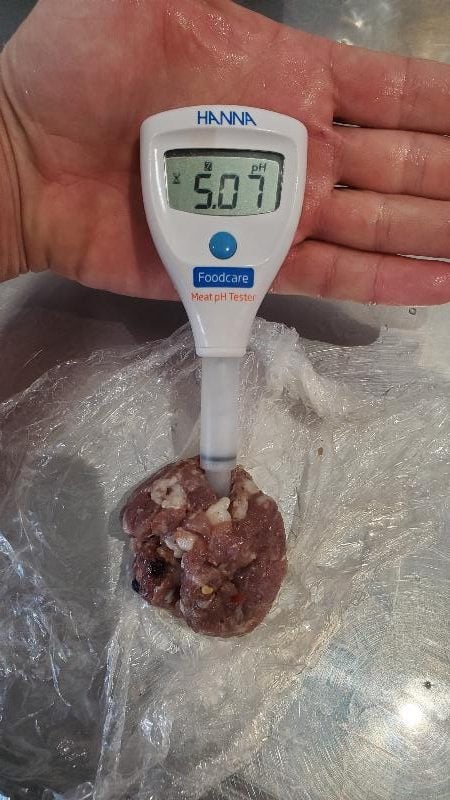

ph testing has been an interesting learning curve.

Most ph Meters have electrodes that will last 12-24 months, the first ph Meter I bought, the one below, cannot attach a replaceable electrode, therefore it’s single-use. I was rather surprised about it, since it’s about $100.

pH Measurements: Tools and Techniques

Some commercial drying chambers have inbuilt ph Meters, currently a friend has one where we make mostly large batch salami. However, it did cost like $20k.

Apera Instruments has a decent model of pH Meters

The Importance of pH in Texture and Shelf Life of Fermented Salami

Maintaining the appropriate pH levels during salami fermentation is essential for achieving the desired texture, extending shelf life, and ensuring product safety.

The acidic environment created through fermentation helps create the characteristic firmness and bind the proteins together.

It also acts as a natural preservative, inhibiting the growth of harmful bacteria and extending the salami’s shelf life. The interplay of pH with flavors contributes to the overall sensory experience, making fermented salami (here is a link to the category on this site about salami) a delight to savor.

Tom Mueller

For decades, immersed in studying, working, learning, and teaching the craft of meat curing, sharing the passion and showcasing the world of charcuterie and smoked meat. Read More