The sour flavor that is quite common in salami, most people are pretty familiar with, I will share what I know about where it comes from.

I make salami at home, and the process sometimes involves a fermentation stage and a drying stage.

Having met a bunch of small and large salami producers, I’ve gained some insight into the subject.

Why is Salami Sour?

Salami is sour because lactic acid is produced during the fermentation process. A lower pH increases the acidity of the environment. Higher acidity helps preserve the salami and sometimes creates sour and tangy flavors.

Since salami is minced meat, it is more exposed to the external environment (oxygen, anything floating around). This means you just have to follow some precautions to make sure the end product is safe and delicious.

The other type of meat curing I do, and that is well known, is whole muscle dry-cured meat, like prosciutto or pancetta. This doesn’t have the sourness because it doesn’t have a fermentation stage.

The sour flavor is produced by lactic acid bacteria in the meat; it is a byproduct of the fermentation of naturally occurring or introduced carbohydrates/sugars in the cured salami.

The fermentation stage is all about lowering the pH level, therefore raising the acidity, which creates an environment that many bacteria that spoil the salami don’t like and can’t survive (For whole muscle drying – salt, nitrites/nitrates, and possibly cold smoke are used).

In the past, fermentation happened naturally. Certain good bacteria hung around the meat-curing producers, providing unique flavors.

Things like wine were used, one fermented product helping another!

In modern times, for the home salami maker, you can buy different types of starter cultures with different levels of acidity and flavor (here’s a scientific brochure link if you’re interested).

This is also what is used for consistency in commercially made salami.

So, in short, here is why salami is sour. Then, I’ll get into a little bit of the nitty-gritty about the delicious and mysterious world of salami – contrasting commercial and small production.

What Does the Sour Acidity do?

It preserves and encourages beneficial bacteria inside the meat. However, it is also sometimes used as a shortcut to producing salami very quickly in some large commercial salami-making factories.

Quite often, that tangy salami taste instantly tells me that the salami was produced fast for profit.

Many commercially made salami are produced in 1 to 2 days versus traditional dry-cured salami, which mellows out over 2 to 5 months depending on the diameter and conditions of drying.

Yes, quality salami takes that long to make! But for me, it’s worth it: intensified flavors, complexity of fermentation, and something to be savored.

Good things take time, like anything in life—the opposite of fast, convenient, thoughtless food.

You’ll find that with traditionally made salami, often over the longer period of time it takes to make, the acidity and sourness can mellow out, becoming more subtle.

This can sometimes be a way of telling salamis apar, in this video it’s highlighted in detail.

After Salami Fermentation

So, I’ve made most of my homemade salami, introducing a good starter culture and holding the temperature at a favorable condition for the culture to develop. This is after the flavoring and salt cure have been mixed through salami and stuffed in a casing.

After salami fermentation, I use a homemade curing chamber to lower the temperature and start the drying process. Sometimes, cold smoking is used, and sometimes, it’s not. This is basically the traditional way of making dry-cured slow-fermented salami.

Lactobacillus

This is a “good bacteria” that is the cornerstone of salami making, it’s the same good bacteria that’s in your gut and all-around your body.

You see it advertised on yogurt a lot.

It’s funny how people are so averse to certain bacteria these days, not knowing that we’re pretty much symbiotic with many good bacteria to exist. So much focus on kimchi, sauerkraut, etc.. all fermented goods!

Commercial-produced salami and Tangy/Sour Flavor

What you’ll find quite often on the back of the commercially made salami is the addition of sugars so the fermentation can happen rapidly. By acidifying the meat quickly, the commercial salami producer can preserve it and sell it much quicker than traditional salami.

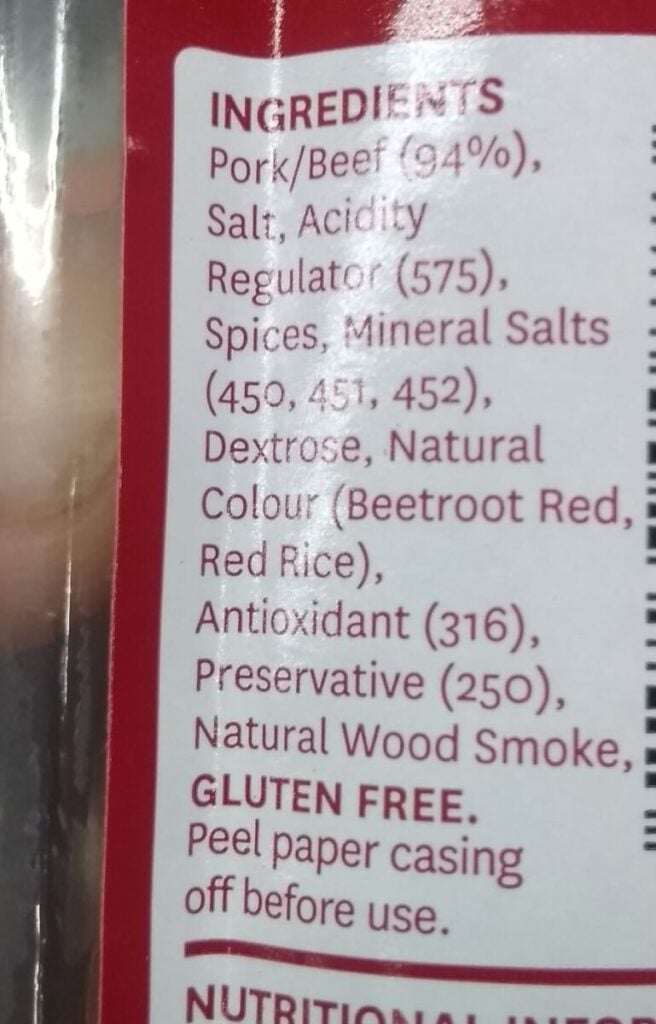

Here is an example of what I consider a large factory commercially made salami:

Dextrose is a pure or easily digestible sugar used to feed the bacteria, so the fermentation happens quickly.

Traditional Salami Ingredients should be:

Meat, spices, salt, preservative 250 (sodium nitrite), starter culture (often meat has sugar, which culture can feed off.

White Powder on Salami: What’s That?

This normally means the salami is the real deal. It provides another protective mold on the outside of the salami.

This is penicillin, a good mold that naturally grows when I make salami. However, it can also be purchased and applied to salami to ensure the protective coating flourishes. It protects the meat and allows the salami (here is a link to the category on this site about salami) to dry out, lose moisture, and preserve it.

For homemade traditional dry-cured salami, the goal is always to lose 35 to 40% of the moisture; it is then considered dried and preserved.

At this stage, the water activity and amount of water inside the salami have been minimized to the point that bad bacteria have a chance to spoil the product.

Tom Mueller

For decades, immersed in studying, working, learning, and teaching the craft of meat curing, sharing the passion and showcasing the world of charcuterie and smoked meat. Read More

Hi Tom,

Thanks for the, great, practical info.

I’ve been making salami occasionally but not the salami I grew up as a kid in Italy. I was told by an “expert” to use the culture T- SPX, the result was terrible … acidic & sharp & couldn’t taste the meat!

Is there a culture I can use to overcome this problem? I’m thinking of not using a culture at all! You mention lactobacillus where can I find this or do you use yogurt ? If so what dose please?

Ciao John!

Interesting! TSPX is the main one i’ve used, it is fast fermentation, check out – https://www.chr-hansen.com/en/food-cultures-and-enzymes/meat-and-seafood/salami-and-pepperoni

I dont think you can re-inoculate after, 1st culture is introduced. But I’ve never tried, it just wouldnt get through meat. For narrow salami like hog casings 30-35mm,I do a Hungarian salami – paprika (same as salt 2.25%), garlic, cumin, pepper and 15 hrs cold smoke. not innocoluation. Dried to 40% weight loss) Though is only take 4-5 weeks to dry! Cheers T

Hi John, just check the amount of dextrose you used. It may also be wise to check your other ingredients to check that there isn’t any that have sugars that are easily digested by your starter culture, thus creating the excess acid taste. Cheers.

Taylor

No worries, yeah some people like the sour some dont!

DO you know if its normal for natural fermentation in sausage can also become sour. I have smoked some sausage for around 6 days. Sort of jachtwurst or kabanos style but i didnt hot smoke it just cold smoke and drying. But the sausage has somewhat of a sour taste not bad or anything. Its actually rather nice. I know some sausage can taste sour because of fermentation like skilandis. I think the flavour is even somewhat comparable with skilandis. I didnt use nitrites btw and the pork is free range from a very small farm.

well i’ve done a little ph meter testing on dry cured salami some which where innoculated with mold culture and smoke without just with some wine. yes the un-inoculated had similar pH acidification. Also, some factory whole muscle meat curing producers I’ve come across do a natural fermentation for a week or 2 at the start for acidity flavoring. – so it’s entirely possible for sure. all the best, Tom