Salami can be made of quality ingredients or additives to drive its profitability of it and make it a high-volume product. Making salami at home as well as buying it commercially, I want to contrast the ingredients and flavors.

Readings textbooks about salami making and meat science have opened my eyes to some of the processes that are used in the modern era of making salami and the ingredients that are added.

For someone who has done meat curing for many years, salami especially dry-cured salami is the type of cured meat you tackle once you have got the basics right.

What you put in, is what you get out

My Salami Making Approach (old but relevant saying)

So as per usual, I’ll give a short answer about what salami is made up of and give it a little bit of structure about it. Then I’ll break down a bit more detail if you’re interested.

Traditional Salami Making – the Art & Craft are a Fine Balance (this is one approach)

What is Salami Made Of?

Traditional Salami is made of these ingredients meat, fat, salt, spices, and often nitrates/nitrites. Commercial salami ingredients may have meat, fat, salt, spices, binders, emulsifiers, preservatives, and sugars.

What is Salami Made of in Detail

Bacteria & Fermented Salami

Meat has bacteria, like many things including all over your skin and inside our bodies. And of course, there are the good guys and the bad guys, curing meat or specifically dry curing involves using salt as the main agent to preserve and fight bad bacteria and promote good bacteria.

Penicillin types of mold culture you’re probably familiar with. You know that white powdery stuff on the outside of the salami?, Yet that’s a type of penicillin just like they used in medical situations.

Penicillin is definitely the good guys, the bad guys come in a few forms, this is one reason why fermentation is used (& nitrates/nitrites). It’s about increasing the meat acidity (so the pH decreases) and lowering its water content generally speaking.

There are some heat-treated salami products that are produced commercially as well.

If you want to go deep into the meat science, here is a link to an Emeritus Professor (Robert E. Rust) of Meat Science talking breaking down salami.

Salt & Acidity Effects on Salami

Lactic Acid has a big role to play, this scientific quote is useful:

Lactic acid can cause pH (acid degree) value in meats to drop to 4.5 to 5.5. This weak acidity condition can make new meat products which have gel-like texture. The behind story is as followed. Low pH value is able to stimulate big muscle proteins to form smaller stuffs by coagulating them. Digested short proteins get together to produce chewing features. This process is associated with salami’s (many meats can be used for salami) attractive texture.

https://blogs.unimelb.edu.au/sciencecommunication/2013/10/04/salami-secret-of-science/

(Intense but it does explain that gel texture)

Large Commerical and Dry Cured Artisan Salami

I know these sound like really broad categories, and they are.

They’re probably are a whole bunch of businesses that fit in the middle. But one big difference between large commercial factory salami and homemade or artisan dry-cured salami is the number of ingredients that are added to the salami (& whether the salami has been heat treated and smashed with acidity change to produce it fast).

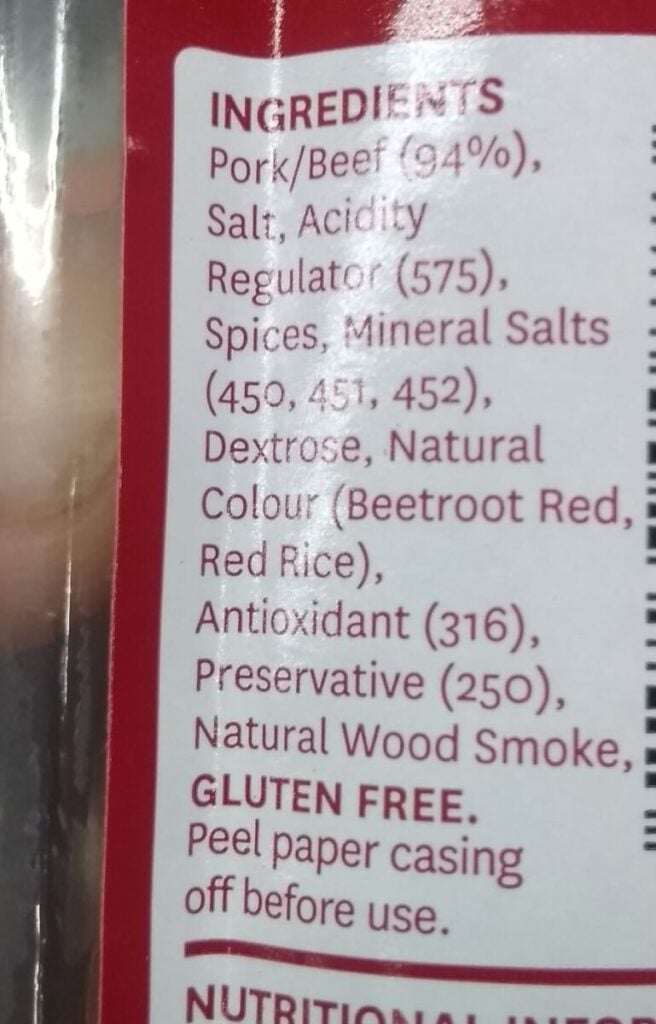

Here is an example of commercial salami ingredients:

Alot of numbers!

- Acidity Regulator 575 = Glucono delta-lactone (a sequestrant, an acidifier,[4] or a curing, pickling, or leavening agent.)

- Mineral Salts 450,451,452 = Sodium and Potassium polyphosphates (water retention agents in food processing)

- Dextrose = Sugar in a sample form

- Antioxidant 316 = Sodium erythorbate (facilitating a faster cure and retaining the pink coloring)

- Preservative 250 = Sodium Nitrite (Prevent botulism, color effect)

These guys do a great salami,

Ingredients: Pork, salt, sugar, white pepper, garlic, white wine, potassium nitrate (saltpeter for color and curing), lactic acid starter culture(change the pH acidity), beef casing.

Artisan or Homemade Salami (Small Scale) Ingredients

Meat

Most of the time when we are talking about sala,mi – pork as the main meat. The quality of the pork can, of course have some impact on outcomes. Beef is also used and mixed with pork frequently.

I have tried a catfish salami as a novelty, it seems to be a novelty product for tourists in a European market of a certain country (Hungary). Probably something that should never be made in the first place in my opinion! (Maybe they don’t like tourists?!)

At home, I like to make wild venison salami quite often. A bit more pleasant on the palate.

Fat

In general, there are soft fat & some hard fats, hard pork back fat is the standard for salami generally speaking. The neutral and pleasant flavor of pork fat is a big reason for this as well.

As opposed to pork belly fat, which can be used but is a bit too soft in general.

Salt

Sea salt is the key to the curing process and really has the main beneficial effect of curing the meat and providing an inhospitable environment for bad bacteria.

Good old sea salt, a point to note is, with meat curing you should be using sea salt that does not have any additives. Like no iodized or anticaking agents – which are both common in your everyday normal table salt (Additives can mess with the curing and flavor of the salami).

Spices

I would probably say black pepper is one of the most popular ingredients in it comes to seasoning a salami across most of the world.

Garlic is also quite prevalent.

But really this is where things get exciting for me and salami. Whether its smoked paprika from Spain or heirloom organically grown variations of chilies.

Nitrates

For the home meat curer – pink curing salt (prague poweder, instacure – it has many names and variations) is used – No. 2 designed for curing over 30 days.

This is mainly salt but also has sodium nitrite and sodium nitrate. These basically break down during the drying process and are a safeguard towards certain bad bacteria.

There’s a lot of dislikes when it comes to nitrates, people need to get a little bit more educated if you do some googling around nitrates and converting to carcinogens it only occurs when cured meats are heated to high temperatures. It is counter in dry-cured bacon with Vitamin C.

Also have a Google of the amount of nitrates inside your body already as well as and a lot of vegetables you’ll probably be consuming every day.

For me personally it’s all about moderation toward consumption too.

Commercial Produced Salami Ingredients

Meat, Fat, Salt, Spices, Nitrates – the above and..

So just to give a bit more information not a scientific complete breakdown but just an overview of why commercial salami uses these ingredients.

A lot of the numbers above on the back of the commercial salami packaging relate to the below:

What May be Included:

Sugar (Dextrose)

A dextrose is a simple form a sugar that bacteria consume in the fermented sausage. Then you’ve got stuff like glucose syrup or corn syrups, which also uses a thickness to make that salami bit fatter.

Maltodextrin is another type of filler to bulk up the salami. Sugar s are of course used for sweeten the salami as well.

Soy Products

Soy proteins are mixed with the mince meat, which creates a sort of gel and holds in the moisture.

Textured Vegetable Protein

A variation of soy protein it’s again used as a filler made from defatted soy flour.

Gums

Gums are all about stopping the water inside the salami. As an ingredient, it’s often a emulsifier and stabilizer too. There are many different popular types of gums that are used. Some of the most popular you probably have heard of or use are cornstarch and gelatin.

Check out the link above to the doctor of meat science if you want to get more of an idea about additives and processes. As I said this is more of an overview.

What is the Salami Casing Made of?

You can get natural animal or synthetic casings when it comes to the salami.

Depending on the diameter of the salami (I’ve written about some of the interesting salami for pasta salad here) -beef or cold casings are used. These are made from the intestines of the animals, they are normally just salted heavily to preserve them for a long period of time under refrigeration. They provide protection to the meat and give it shape. They allow for some airflow during the drying aspect of slow dry-cured salamis.

The other type is a collagen or cellulose casings, have a very different feel.

Cellulose casings may be derived from cotton linter or wood pulp.

You can get natural or synthetic casings when it comes to the salami.

Collagen casings can be derived from pig or beef hides, bones/tendons.

What Meat is Used in Salami?

No gristle, sinew, blood clots or glands. These things can hamper the mincing process or have a negative effect on the salami.

What Piece of the Animal is Salami Made of?

Many cuts used are often the back legs of the animal, as well as offcuts of muscles – when the meat is chopped up. But generally speaking, it’s whole muscle that has been trimmed up nicely you would hope.

Smoking a Salami As an Ingredient

Anti-bacterial and Antifungal Effects

I don’t always, but sometimes I cold smoke the salami, you’ll find many European salamis are cold smoked, especially in central and northern Europe.

Traditionally cold smoking was used for its beneficial antibacterial and antifungal properties. Also to keep off any bugs and deliver the flavor as well.

In its simplest form, cold smoking is a smoldering piece of smoking hardwood in the chamber with some airflow and under 85°F or 30°C. Generally speaking, cold smoking is done at much lower temperatures than this.

Cold Smoking is an ingredient in many salami products. There is another shortcut that’s used sometimes with commercial salamis and that’s adding a liquid smoke, which is a concentrated additive.

Tom Mueller

For decades, immersed in studying, working, learning, and teaching the craft of meat curing, sharing the passion and showcasing the world of charcuterie and smoked meat. Read More